Argentina Wheat Flour Production

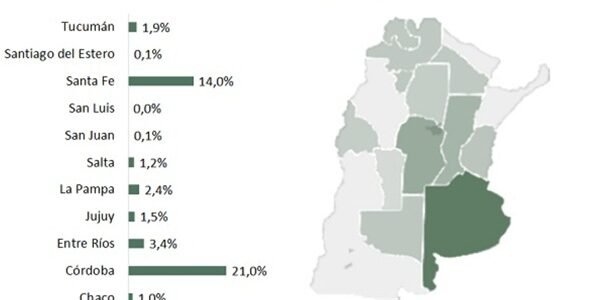

Consistent with the geographical location of wheat production, most of the mills are located in the province of Buenos Aires, implying a participation of more than 53% in the 2020/21 cycle. Then, Córdoba is second, registering 21% of the total milling and Santa Fe is in third place with 14% of the processing of national bread wheat. In a smaller proportion there are other 9 provinces from different regions of the country.

Consistent with the geographical location of wheat production, most of the mills are located in the province of Buenos Aires, implying a participation of more than 53% in the 2020/21 cycle. Then, Córdoba is second, registering 21% of the total milling and Santa Fe is in third place with 14% of the processing of national bread wheat. In a smaller proportion there are other 9 provinces from different regions of the country.

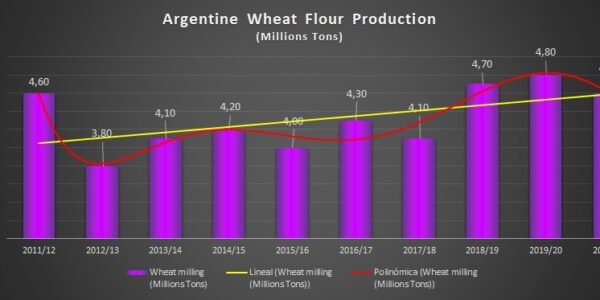

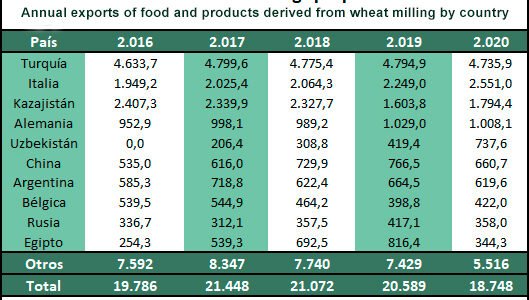

According to data from the International Grains Council (IGC), the domestic consumption of bread wheat in Argentina for human consumption in the 2020/21 campaign would be 5.2 Mt. In other words, it is estimated that approximately 91% of what milled within the country is absorbed locally, while the rest of the milling would be destined for exports. In this way, about 4 million tons of bread wheat flour would be consumed within Argentina, which represents barely 1% of the world’s absorption of flour, far behind China and India, which account for 17.6%. and 16.6%, respectively.

Productive Process

Our supplier has a recently modernized plant, it is state-of-the-art, the modernity of its facilities, its processing capacity, added to its own logistics and distribution, allow it not only to ensure a high quality of the finished product, but also to be within the highest standards of global market demand.

Our supplier is always at the forefront with the latest industrialization and process automation technologies, it has a team of highly trained technicians and engineers to respond to production processes to guarantee the highest quality with the optimization of these processes.

Strict quality standards are applied daily in production processes and laboratories, thus ensuring that a product with high performance and optimal features reaches the end customer.

Quality System

The production processes are certified with the ISO 9001 quality standard.

They have also implemented and adapted their Quality system in accordance with the IRAM NM 324:2010 Standard for Good Manufacturing Practices in Food Industries, guaranteeing the stability of their products.

Maxitrigo 0000 Type 1

It is a flour with a low ash content, with a characteristic creamy white colour. It is a product with a finer granulometry than “000” type flours, made from a careful selection of semolina from the first stage of the milling process.

It is mainly used in partially dehydrated and dry pasta, products that are favored by the color of the dough and the low bacterial load that these flours provide. Also for pastry products and sliced bread.

Maxitrigo 000 Type 1

This flour is characterized by being the product of a careful classification and selection of the best quality wheat with the highest protein content.

Contains additives that ensure normal development in the different baking processes, thus achieving products with a high specific volume, crispy coretza and good color; crumbs with a uniform structure that preserve their initial freshness for longer. It is a highly versatile flour that adapts to most bread-making methods: long fermentations (Table Method) and short fermentations (Direct and semi-direct Method).

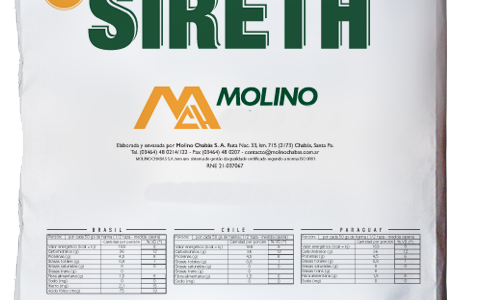

Sireth 0000 Type 1

It is a flour with a low ash content, with a characteristic creamy white color. It is a product with a finer granulometry than “000” type flours, made from a careful selection of semolina from the first stage of the milling process.

It is mainly used in partially dehydrated and dry pasta, products that are favored by the color of the dough and the low bacterial load that these flours provide. Also for pastry products and sliced bread.

Sireth 000 Type 1

This flour simplifies work by eliminating formulation errors, minimizing variations in the finished product and avoiding the weighing of ingredients, it generates more tolerant doughs during preparation, allowing the obtaining of optimal quality bread, also reducing the total time used. This formulation does not require the addition of additives, it should not be mixed with other flours or premixes and only salt, water and yeast should be added.